The Shield water bottle provides the purest drinking experience on the market, utilizing a unique force filtration process that provides fresh water fast and can be cleaned quickly and easily.

|| Overview

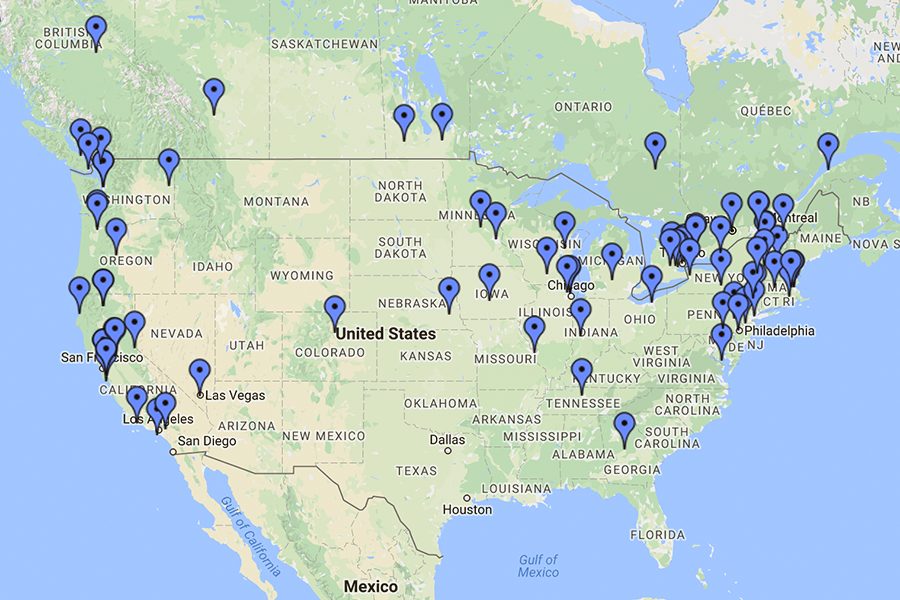

This project was a theoretical design brief for the Rubbermaid brand, anticipating the rising trend of bans on the sale of disposable water bottles on college campuses. Environmentally-conscious universities across the country are limiting the sale of disposable water bottles on campus, increasing the demand for reusable bottles as a result. In areas where an aging public water infrastructure leaves taste-affecting and potentially harmful particulates in the public water, filtered water bottles are preferred.

Shield is a water bottle that utilizes a novel filtering process to provide the cleanest drinking experience available on the market. Shield targets the male undergraduate student population, and was designed within constraints specific to this target market.

|| Problem

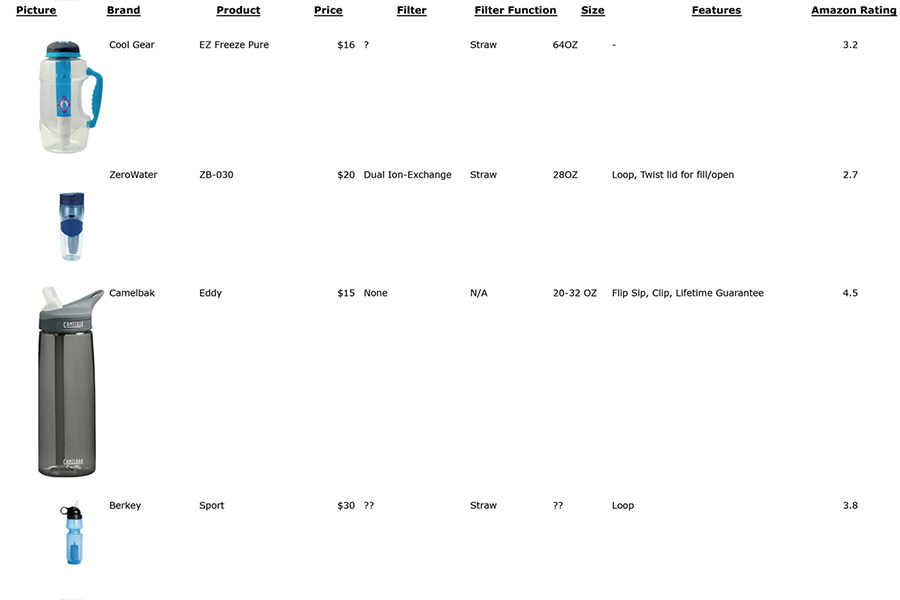

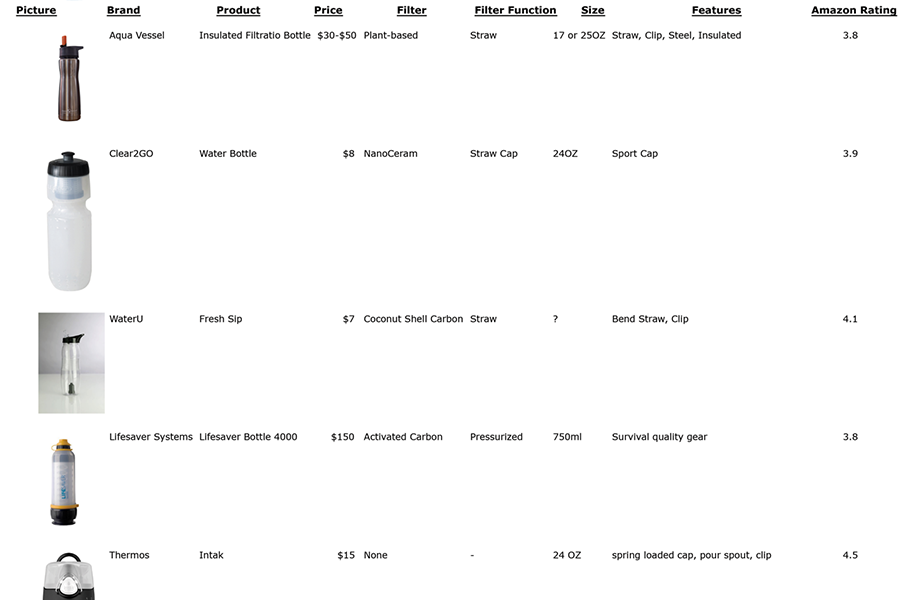

Through a process of framing research on water bottle bans and the competitive landscape of filtered water bottles, it became clear that the new bottle must target an undergraduate customer as the vast majority of bans occur on college campuses. As of 2016 there are over 80 universities in North America banning the sale of disposable water bottles.

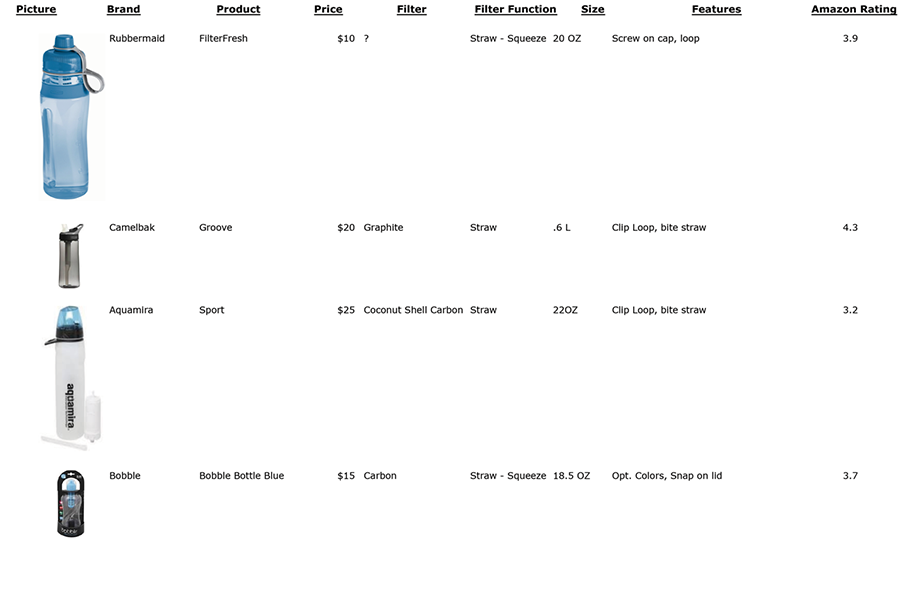

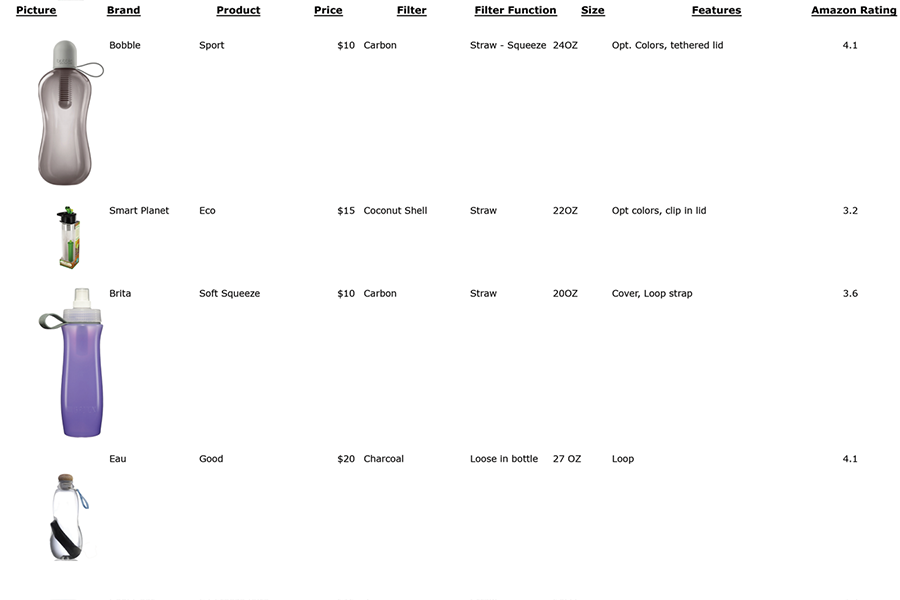

Competitor research revealed that current filtration methods are lacking in purification ability and user experience. Other filtered water bottles drip water slowly through the filter and take hours to filter a full bottle, filter passively which leaves doubt as to effectiveness in the consumer's mind, or require you to suck water through a filtering straw as you drink which is less purifying due to minimal filtration force. And most bottles, even the few that do use force filtration, leave particulates floating in the bottle with your drinking water.

“Current filtration methods are lacking in purification ability and user experience”

|| Solution

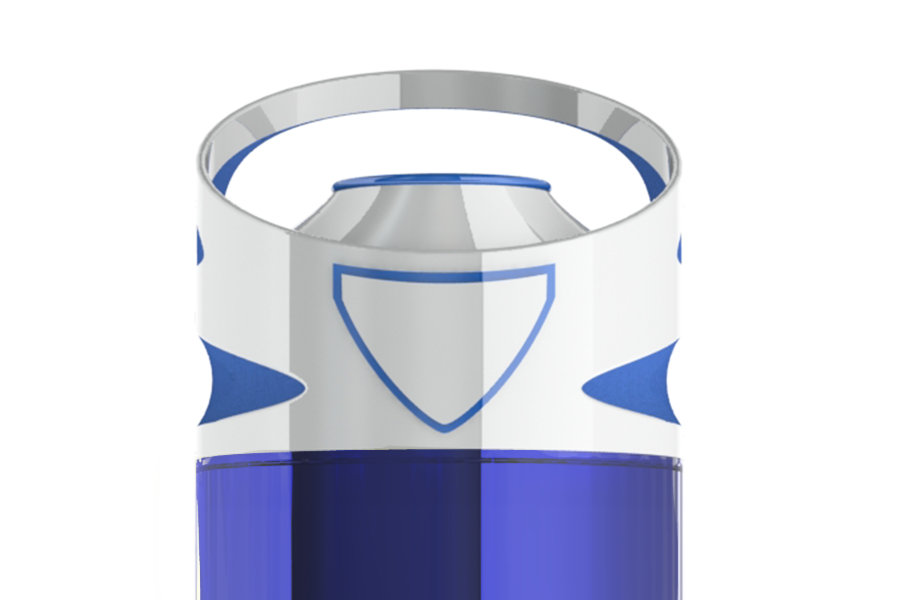

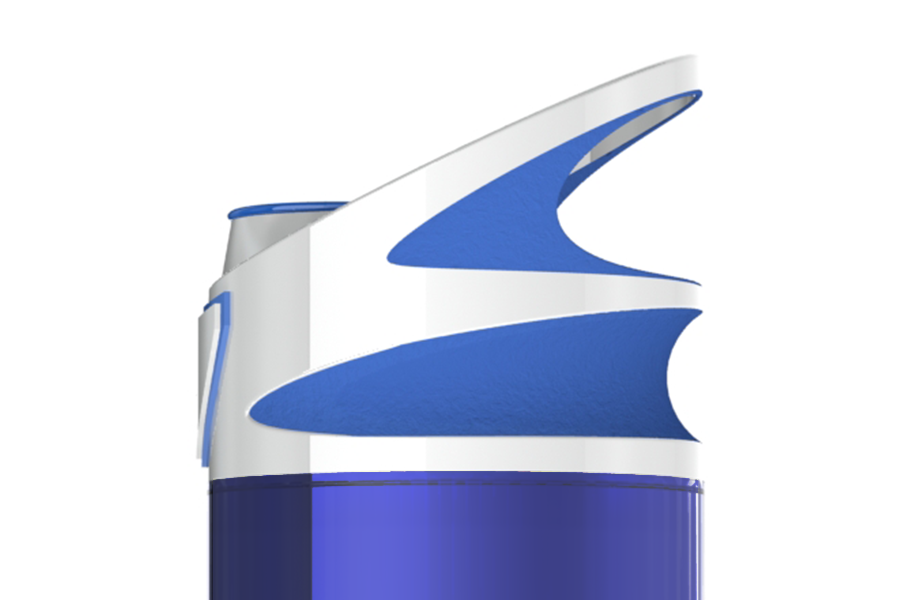

Shield's innovative design provides confidence that every last drop of water from your bottle is filtered and pure before it hits your lips. Shield's manual force filtration process takes the guess-work out of water filters by separating filtered and unfiltered water into separate reservoirs. With the Shield System™ you push the water through the filter yourself, leaving you with a full reservoir of pure water that never even touches particulates, and a shell that can be easily washed or rinsed whenever you refill.

To fill Shield, hold the valve button while you pull the reservoir out from the shell. Fill the shell up to the fill line with tap water. While holding the valve button, press the reservoir back into the shell until it snaps into place, forcing all of the water through the filter and into the reservoir. Now enjoy a sip of refreshingly clean water whenever you want, without having to suck it through a filter.

“A full reservoir of pure water that never even touches particulates”

|| Process

Sketching

Rapid Prototyping

3D Modeling

Looks-Like Model